which is a type of machine safeguarding

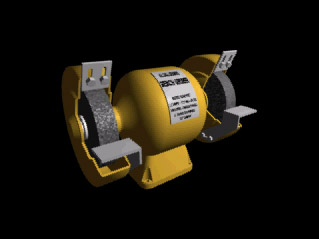

Area on a machine where the work is performed. Various types of machine guards available for machine guarding.

Methods of Machine Safeguarding.

. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area. Guards are barriers which prevent access to danger areas. Most usable machine guards are described below.

We can group machine safeguards under five general classifications. Machine safeguarding helps protect workers from preventable injuries in all three areas. All machines consist of three fundamental areas.

Safeguards are essential for protecting workers from these preventable injuries. Despite all machines having the same basic components their safeguarding needs widely differ due to varying physical characteristics and operator involvement. Fixed guard on bandsaw.

There are many ways to design and use machine safeguarding. Ad Mitigate Risk Ensure Compliance With The J. Which of the following is a type of machine safeguarding punchink feeding and ejection methods point of operation in-going nip points Feeding and ejection methods is a type of machine safeguarding.

Their suitability should be selected. Each piece of machinery has its own unique mechanical and non-mechanical hazards. What are the 2 types of primary safeguarding methods.

B Maintenance is minimal and. A safety device may perform one of several functions. Basics of Machine Safeguarding.

Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines. There seem to be as many hazards created by moving machine parts as there are types of machines. Machine guards are your first line of defense against injuries caused by machine operation.

Primary Safeguarding Methods Two primary methods are used to safeguard machines. There are four general types of guards and well discuss them in the next section. Transform Your Business Today.

Restrain or withdraw the operators hands from the danger area during operation. The most common types of machine guards are. Which of the following is the definition of point of operation.

Basics of Machine Safeguarding. A fixed guard is a simple device attached to the machine designed to cover hazardous mechanical motions and prevent entry from hands or fingers. Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying.

Each machine must have adequate. Which of the following is not a common type of. Fixed Adjustable Self-Adjusting Guards.

Start Your Free Trial Today. Contents hide 1 Fixed guards. The type of operation size or shape of stock method of handling physical layout of the work area type of material and production requirements or limitations will help to determine the appropriate machine safeguarding method for the.

2 Fixed limited access guards. Require the operator to use both hands on machine controls thus keeping both hands and body out of danger or provide a. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area.

Machines can cause a variety of injuries ranging from minor abrasions burns or cuts to severe injuries such as fractures lacerations crushing injuries or even amputation. 3 Fixed adjustable access guard. Wrists are connected by cords and secured to a fixed anchor point which limit operators hands from reaching the point of operation at any time.

Interlock into the machines control system to stop operation when the sensing field photoelectric radio frequency or electromagnetic is disturbed. A well-designed fixed guard will also prevent the operator from reaching over or under the guard into the point of operation. OSHA Safety and Health Information Bulletin SHIB January 25 2013.

A safety device may perform one of several functions. It may stop the machine if a hand or any part of the body is inadvertently placed in. The following pages address the general requirements for machinery set forth by.

Any machine part function or process that may cause injury must be. Basics of Machine Safeguarding. Keller Safety Management Suite.

Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness. Safeguards are essential for protecting. Types of Machine Guarding Restraint Devices.

Also asked what are the most common types of machine guarding. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal Regulations CFR 1910 Subpart O Machinery and Machine Guarding as detailed below. A Servicing or maintenance is not hazardous for employees.

The point of operation the power transmission device and the operating controls. Which of the following is a type of machine safeguarding. Feeding and ejection methods.

Six Types Of Machine Safeguard Devices

Best Whirlpool Refrigerator Service Centre In Hyderabad Refrigerator Service Whirlpool Refrigerator Whirlpool Fridges

Etool Machine Guarding Introduction Hazardous Motions Actions Occupational Safety And Health Administration

Etool Machine Guarding Introduction Hazardous Motions Actions Occupational Safety And Health Administration

Machine And Equipment Safety 1

Pin On Home Appliances Collection

Safety Measures To Prevent Accidents At Construction Site Prevention Simple Signs Accident

Six Types Of Machine Safeguard Devices

Six Types Of Machine Safeguard Devices

In August 2018 Google Incorporated Voice Navigation In The Navigational Platform For Pu Navigation System Information And Communications Technology Navigation